-

Peer Fin Tubes

Peer Fin TubesLeading Manufacturer of

Heat Exchanger, Finned and Boiler Tubes -

Welcome to Peer Fin Tubes

Welcome to Peer Fin TubesIndustry standards begins with imitation

but ends in Innovation -

We are Peer Fin Tubes

We are Peer Fin TubesWe are the Top Industrial Manufacturer providing

the highest quality products

- Leading Supplier

- Certified ISO 9001 : 2008

- Manufacturer of Low Fin Tubes

- Award Wining Firm

- English

- Mon - Sat : 9.00 - 19.00

- Sunday : Closed

- +91 - 9623207910

- sc@peerfinengineers.com

- Downloads

- PDF Brochures

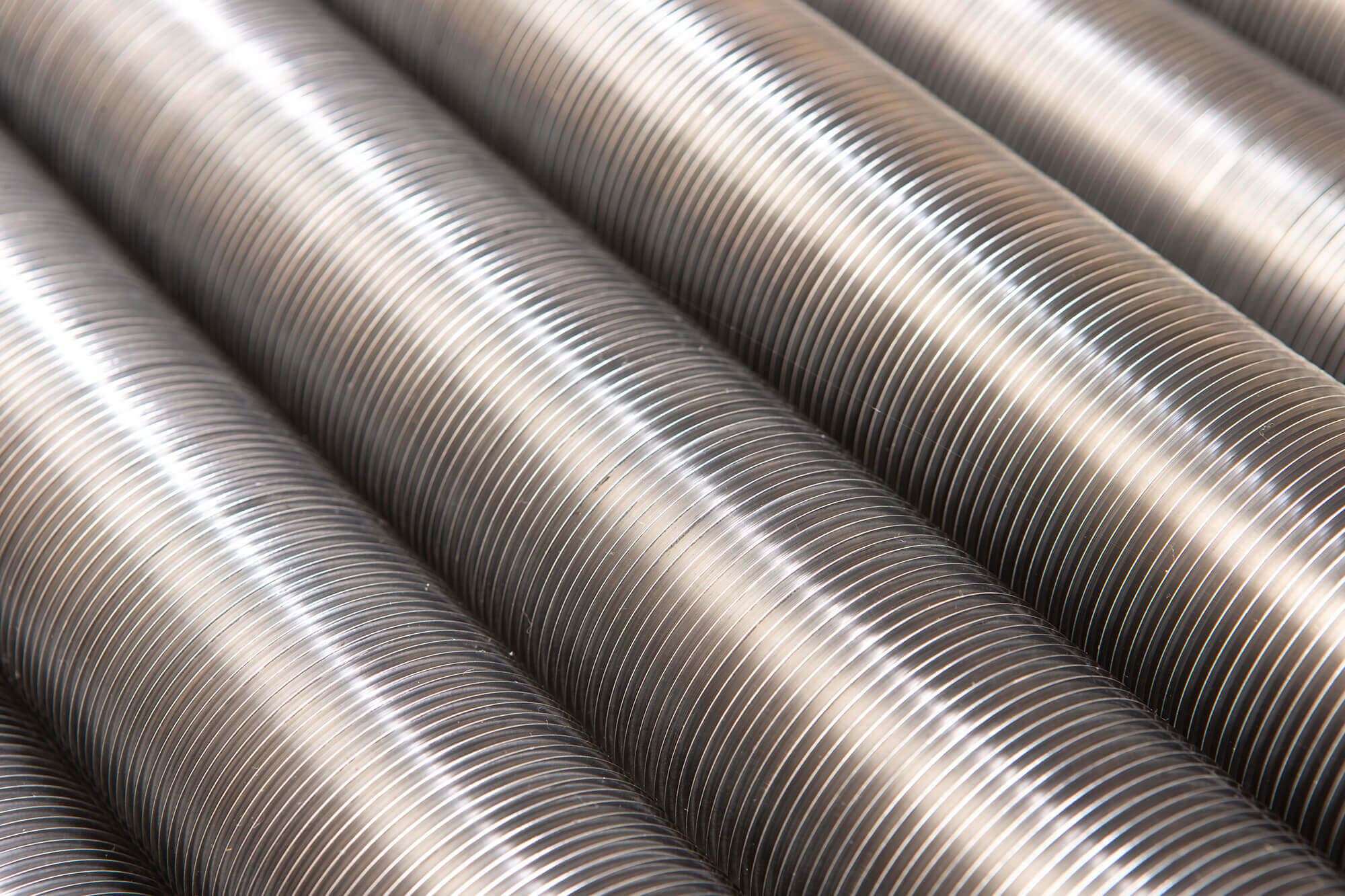

Low Fin Tube Manufacturer

We are leading manufacturers of Low Fin tubes in Maharashtra and Gujrat, we have decades of experience in this and a young dynamic professionals to carry this out.

Dedicated Team

We have a proven history of successful, long-term relationships with clients globally. Our professional & Dedicated teams are good in building lasting relationships and working together efficiently.

Long-Term Relationship

We have a proven history of successful, long-term relationships with clients globally. Our professional teams are good in building lasting relationships and working together efficiently.

Quality Assurance

For standalone testing services, Peer Fin Tubes provides you with a multi-skilled QA & testing team. Experts are chosen based on their skills and qualifications to suit your project’s demands.

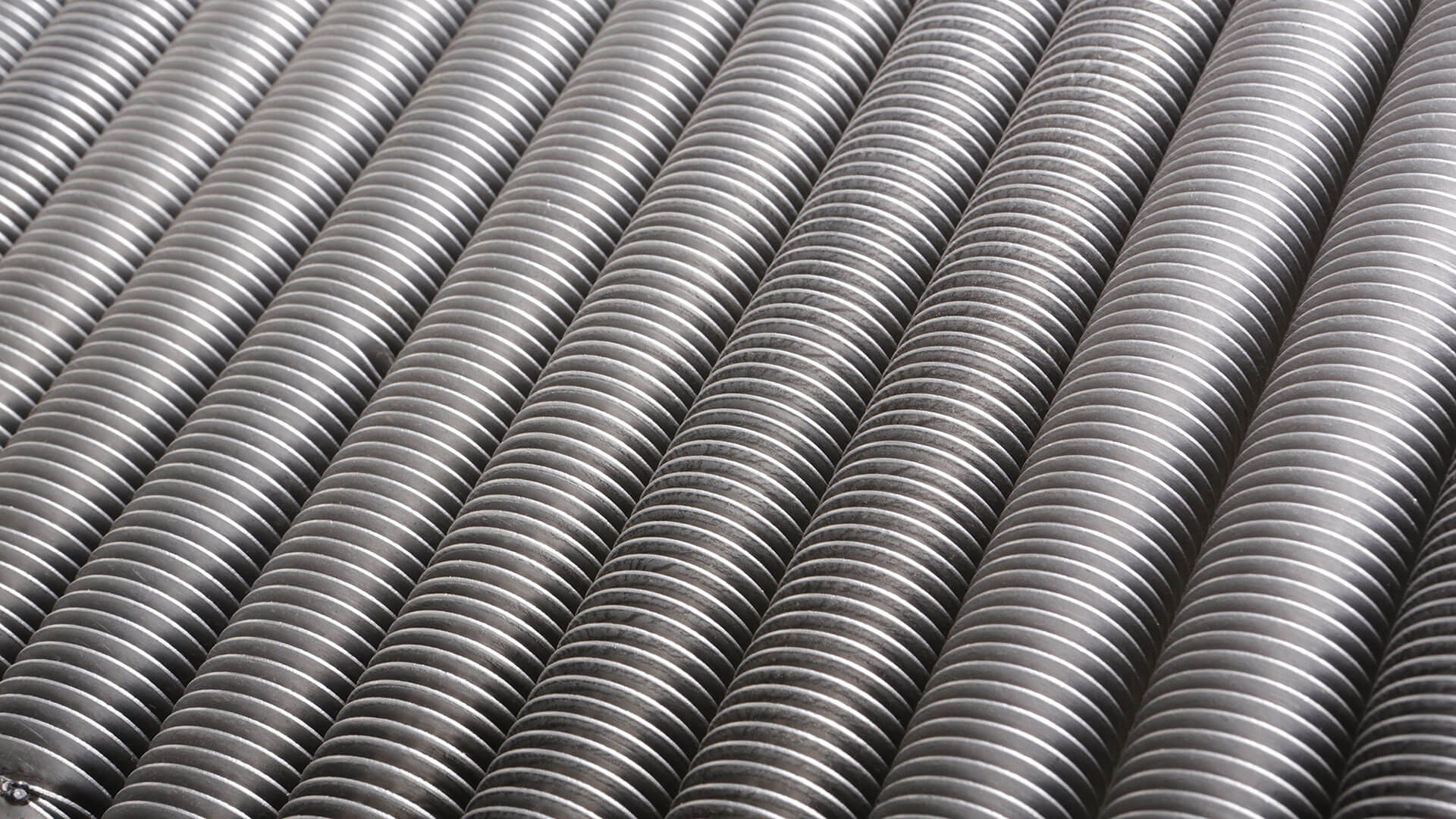

Our Featured Products

We are leading manufacturers of Low Fin tubes in Maharashtra and Gujrat, we have decades of experience in this and a young dynamic professionals to carry this out.

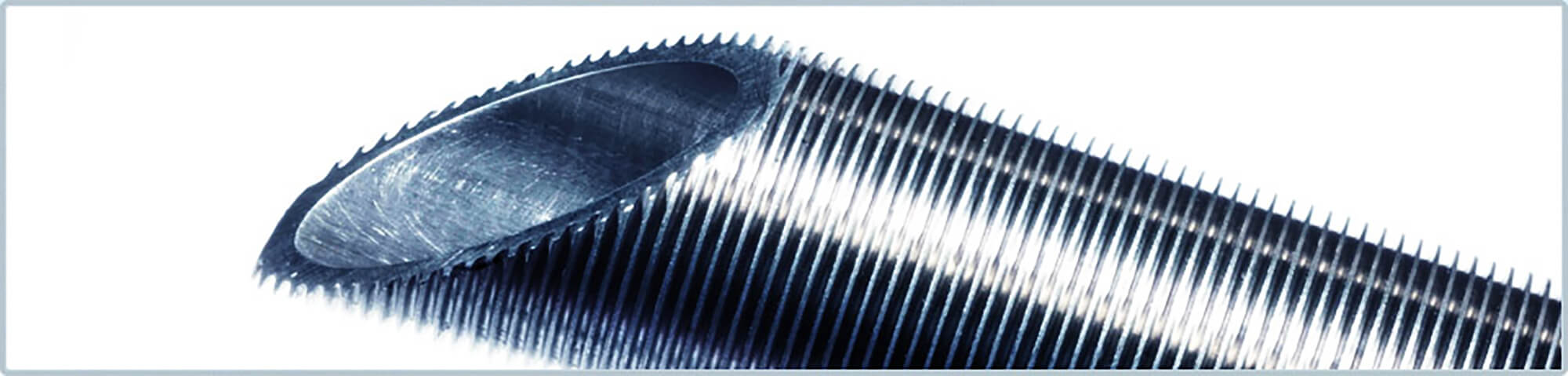

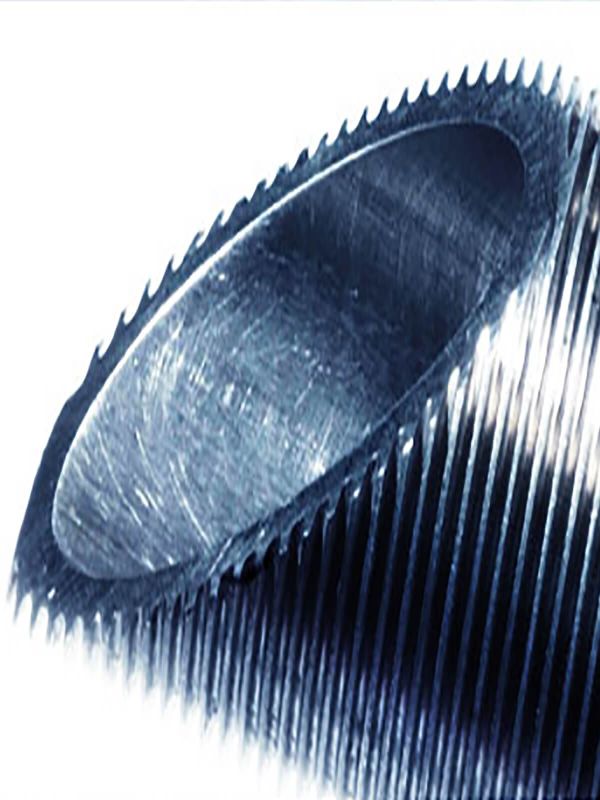

Peer Fin Tubes can produce low finned tubes to meet the most demanding requirements. Our low finned tubes are used in shell and tube heat exchangers.

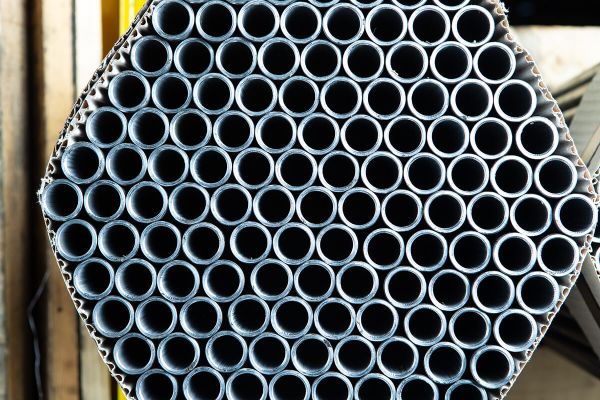

Peer Fin Tubes has an extensive range of boiler and stay tubes available to meet your boiler tube requirements no matter how demanding.

Peer Fin Tubes can produce low finned tubes to meet the most demanding requirements. Our low finned tubes are used in shell and tube heat exchangers.

As a leading manufacturer of finned tubes, Peer Fin Tubes has the facility to produce and supply finned tubes to suit all applications..

Over decades of years we have build our product library, feel free to have a glance of it.

Frequently Asked Questions

-

Why use FIN TUBES instead of regular tubes?

a)The Integral fin tube is a tube where the external surface of the tube is enhanced by the process of fining and fins are drawn from the base material of the tube , resulting in increase in the surface area by 2.5 times than the plain tube area.

b) Increases the heat transfer rate as the outer surface is increased.

c)Reduce the cost (as it reduces the number of tubes required )

d) The size of the heat exchanger is reduced i.e saving the space in the process plant. -

What is a heat exchanger ?

Transfer of heat from one fluid to another is an important operation for most of the industries. The most common application of heat transfer is in designing of heat transfer equipment for exchanging heat from one fluid to another fluid. Such devices for efficient transfer of heat are generally called Heat Exchanger.

Amongst of all type of exchangers, shell and tube exchangers are most commonly used heat exchange equipment. The common types of shell and tube exchangers are:

a)Fixed tube-sheet exchanger (non-removable tube bundle):

b)Removable tube bundle

c)Floating-head exchanger

d)U-tube exchanger -

How to choose the FIN TUBES ?

As per the requirement of the client we at peerless tubes and engineering take the pleasure of designing the finned tubes so that they can get the maximum heat transfer coefficient with higher efficiency of heat transfer.

There are various types of fin tubes and each of them have their unique application according to the need.

-

Where are the FIN TUBES used ?

The applications of fin tubes finds its way through a variety of industries such as :

a) Chemical industry

b) Oil and gas industry

c) Refrigeration

d) Boilers

e) Evaporators

f) Economizers

g) Different combined process cycles

h) Vaporizers. -

How can I assure using finned tubes will be beneficial for me ?

Drop us a mail or call us with your requirements our team of experts and designers will get back to you with the most productive result possible. Or you use the contact us section and fill our enquiry form but if you are in urgent need then call us directly we will try our best assisting you on high priority.

.jpg)